Early filtration products were designed to protect mechanical equipment, mostly combustion engines.

In recent decades, Indoor Air Quality (IAQ) has become a primary focus, especially as it relates to our health and comfort at home, at work or in transit. It also relates to advance technologies for clean-rooms in a health care setting, semiconductor chips in a manufacturing facility, or artwork in a museum.

As air filtration technologies vary greatly, choosing the right product is a key decision to ensure proper supply or air flow and quality. When assessing or testing the performance of different types of air filters, it is important to consider three major factors:

Efficiency: The percentage of airborne particulate the filter will remove.

Capacity: Refers to “Pollutants-Holding Capacity” which is the amount of dust the filter will hold before it needs to be changed. New standards also measure the amount of “harmful” gases that are captured by the filter.

Resistance: Refers to “Pollutants-Holding Capacity” which is the amount of dust the filter will hold before it needs to be changed. New standards also measure the amount of “harmful” gases that are captured by the filter.

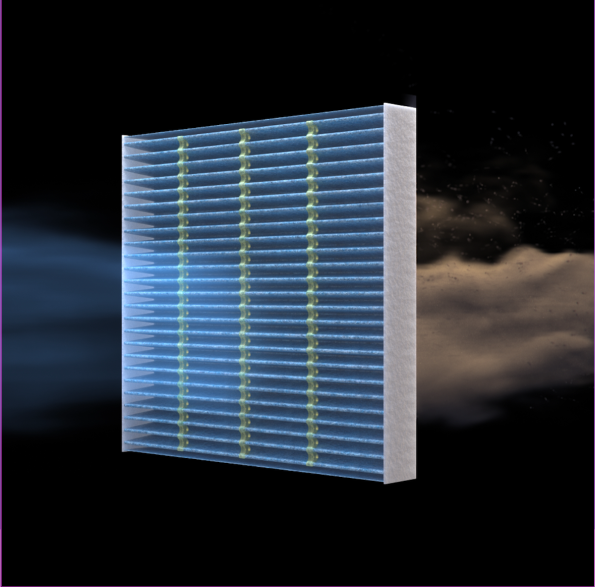

There are four methods of mechanical filtration. One or more methods are utilized in various air filter products depending on the type and grade of filter. The four methods of filtration are:

Straining is the most prevalent method of particulate removal in low efficiency and economy air filters.Straining occurs when the smallest dimension of a dust particle is greater than the opening between media fibers.

Inertial Impingement: This process occurs when a large, dense particle cannot follow the airstream around media fibers, and it collides with the fibers. The particle then attaches to the media. Sometimes the media is coated with an adhesive, which helps keep particles attached to the media. This is the dominant method of particulate removal in low efficiency high flow air filters.

Interception occurs when a dust particle follows the air streamlines and it is attracted to the fiber as it passes around it. If the forces of attraction between the fiber and the dust particle are stronger than the airflow dislodging forces, the particle gets removed from the air stream.

Diffusion: This process occurs with very sub-micron particles which have very little mass. Air molecules impact how these small particles move through the filter media. The particles collide with the air molecules and move in an erratic path (Brownian movement). The erratic pattern increases the probability that particles will encounter the fibers and will stay attached to them. Diffusion is the dominant method of particulate removal in high efficiency air filters.

The overall collective efficiency of a filter is the sum of different filtration effects, Both the interception effect and the inertial effect increase with increasing particle size, whereas the diffusion effect decreases

Always be at the forefront of Pureflow air filter products by reading all of our blogs!